Note that I’m using polyurethane paint prepared with the color code RAL 6020. This is a code I found on various forums dedicated to the Traction, it gives good results.

15six_212

After checking the crankshaft clearance, Claude decides to remove one of the adjusting washers to reduce the gap. Each washer is 0.05 mm thick I believe

15six_213

Then we put back the timing gears with the new chain. The right gear is tighten with huge force, using an impressive extension

15six_217

Before closing the bottom of the engine, we put back the oil pump grill, which required a good cleaning as it was packed on most of its surface

15six_223

Here is the new clutch disk. There is no need for a centering tool, we simply use the gearbox axle, thanks Mister Citroën

15six_224

Claude believes the clutch plate is good enough, so we just put it back after cleaning and lubricating

15six_225

Now that the engine is closed, I’m alone and ready for a long cleaning phase, which starts with the oil pan

15six_231

After sandblasting them, I put back some parts on the engine because they need to be painted at the same time

15six_232

I put some primer on non-aluminium parts to avoid getting rust on them before being ready to paint

15six_243

This preparation is the occasion to discover the molding markings on the engine. The “6D” at the end of this one means that the engine block has been molded during June 1954

15six_244

Also, the “6D” marking on the gearbox has the same signification. So it seems to confirm that the engine and gearbox are the original ones. Good news !

15six_245

I then do some sandblasting on the gearbox levers and here is one I took out of the sandblasting cabinet…

15six_246

… to show you how thick was the layer of paint, dirt and other unidentified products. But the good news is that all that mess did a good protection job

15six_247

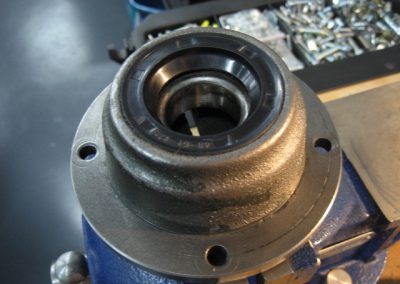

Then starts a tricky task: reinstalling the lip seals on each transmission axle housings. At first, this is not too bad, with a first seal installed, using a wheel bearing as guide and using a hammer with significant force…

15six_250

With a hydraulic press or a bench vise, it just doesn’t work, the seal is soft enough to compress itself and lose its shape, but it doesn’t go into place correctly

15six_251

So I go to a local seal specialist with the original seal (upper left), the one sold by Traction parts suppliers that doesn’t fit (upper right) and he finds in his stock the seals shown at the bottom of the picture (both sides). Awesome ! They are made from steel, so they should be easy to install, without losing their shape and bend all the time

15six_252

And as expected, after a few seconds, each seal goes into place without complaining. Here is a big problem solved, the good way I believe, using the right part at the right place

15six_258

I want to paint the drivetrain with a paint gun in one piece so I prepare with a paint brush some sections that will be difficult to reach, or not reachable at all, with the gun, once the gearbox will be back onto the engine

15six_260

Same thing for the engine, I prepare some sections difficult to paint. In fact the result is that I may extend this preparation to the whole block and head, to be confirmed

15six_262

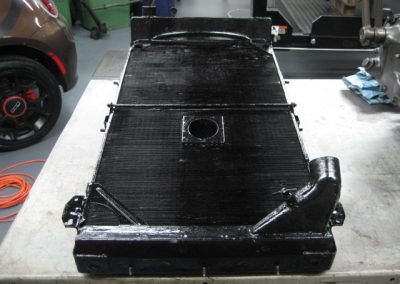

I’ve sent the radiator to a specialist for an overall check and cleaning but he’s not a paint specialist…

15six_265

So I ask another specialist to remove that paint and clean everything again. Then I do the paint myself…

15six_267

… I should not have switched to a different paint brand but my usual paint was not available when needed