15six_362

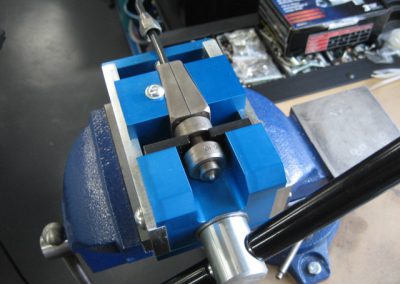

I use for the first time my special tool to shape the flare at each end of the tube, with a common flare shape or the Citroën specific one. Here this is a common flare, made in three steps, the first one is to position the tube correctly

15six_364

Here is what it looks like. I needed a few tries before getting a good result… so I had to shape another line because my first flare was not good at all. That’s the usual “try and error” process 😉

15six_368

… and I install the line. Here at the front the shape is not the final one, I wait for the connection fitting to be back into place

15six_372

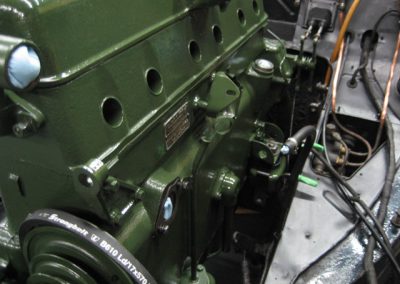

Here are the engine mounts with their new paint. I found some green paint on them so I painted them green again, but I think this is not their original color

15six_373

Here are the new transmission axles, they are not identical to the original ones (they don,t have the “bibax” shock absorbers)

15six_377

Then comes a big moment, the drivetrain reinstallation. I did that alone and it went very well

15six_379

I put the drivetrain back without the front mount, I thought i will be easier that way and it was, especially when the transmission plates have to go through the front axle

15six_385

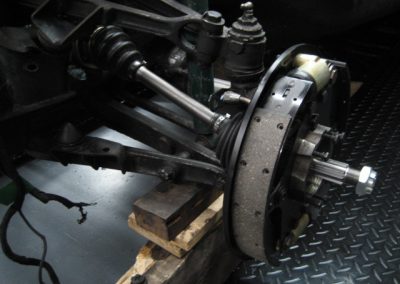

For a few days I had big doubts about the transmission axles, I thought they were too short…

15six_388

To clarify the situation I tried to reinstall the brake drums, beginning with the installation of the wheel bearings, but I positioned the rings the wrong way…

15six_391

… to eventually putting the bearing back the way it should. But anyways I was not able to reinstall the drums 😉

15six_392

Eventually, by measuring the section of the axle that goes inside the pivot, on the new and old axles, I was able to confirm that everything was OK. It has been very worrying 😉

15six_399

For the exhaust manifold, one of the 7 mm studs had been replaced by a common 8 mm bolt. So I bought new 7 mm studs and some repair studs (7 mm on one side and 8 mm on the other side), here on the left of the picture. I’m very happy of having found that

15six_400

I install all studs but the 8 mm thread seems weak and too short, so I’m going to order and install a “helicoil” repair thread

15six_402

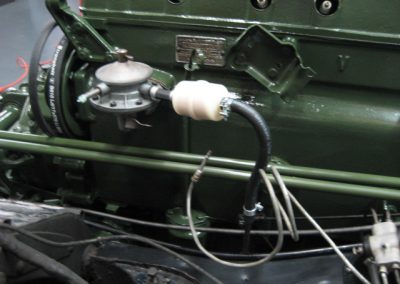

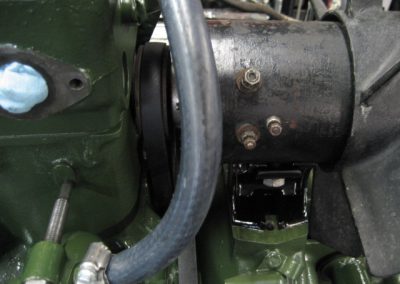

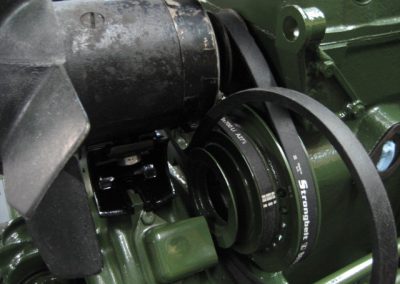

I initially thought that the belt was too short because the dynamo is not centered on its mount, but I saw on pictures that it was not centered before anyways

15six_403

But putting it back into place was has not been easy, I had to use straps to position and align the dynamo

15six_407

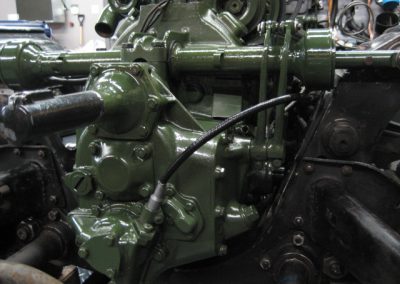

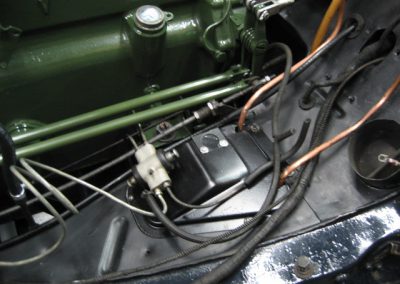

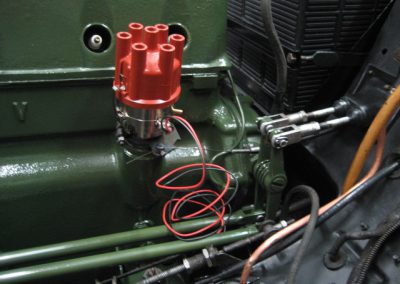

The “123Ignition” electronic distributor then takes place. I’m happy with those I installed on the SM and the Jag so I do the same for this Traction

15six_408

I then put back the hydraulic pressure regulator, overhauled, with a new accumulator sphere

15six_410

I then call Claude and Dominique to help me. In three days we’ll make huge progress. We start by reinstalling the flexible brake lines

15six_411

I had made a replica of the special tool dedicated to the adjustment of the front brake shoes… but we discover that we won’t be able to use it because it doesn’t fit correctly onto the pivot and around the wheel bearing. I’m very disappointed

15six_415

Silicone brake fluid (DOT5) was used but here in North America this kind of fluid is colored purple, so we won’t just mix, we’ll replace the whole fluid

15six_416

The bleeding operations is then a success, so the new brake line and all connections seem OK

15six_417

Two repairs, horrible and with no insulation, were done on the wiring harness, Claude works on doing a clean repair

15six_420

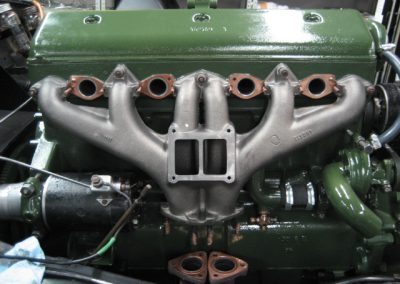

The exhaust manifold is back, after having installed, as planned, a “helicoil” repair thread to secure the repair stud located at the very left

15six_426

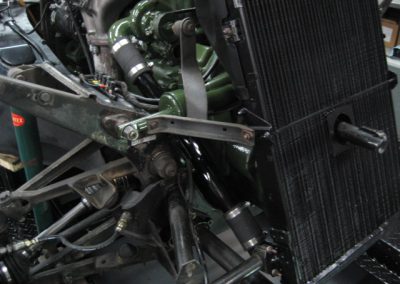

The exact position of the radiator will be set later, with the front grill, side panels and hood

15six_428

Between the radiator and water pump a simple straight hose was installed, I fitted a steel tube, as it was originally

15six_429

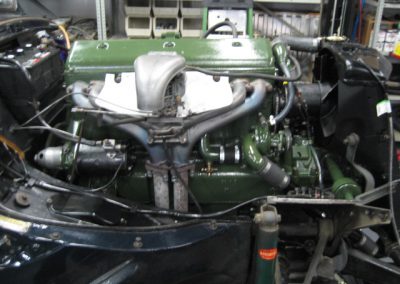

Here it is, we are ready to star the engine. As the hydraulic circuit is not ready (at this point I did not paint the tank yet), I remove the belt driving the hydraulic pump

15six_430

It doesn’t start immediately because I made a beginner mistake while setting the engine on the timing point, I was one turn off, but once this issue fixed, the engine starts and the exhaust manifold begins to change color

15six_431

Because I plan to install a coolant expansion tank, I removed the radiator pressure valve, so we had to install something temporary to take what’s coming out from the radiator

15six_436

Before putting back the front grill, we install an electrical fan, it will allow to face big traffic jams, they are quite common in the Montreal area

15six_442

… this is not easy to align all these body panels, with also the radiator. By the way, this is not perfect

15six_443

As we did for the front brake circuit (right bottle here), we replace the fluid for the rear circuit (left bottle). This car has been equipped with a double brake master cylinder

15six_444

The additional headlights were simply not connected so Claude connects them, by installing a protected (fused) relay located underneath the voltage regulator using an existing hole on the fire wall

15six_445

Here is the beauty with all her clothes. Thanks to Claude and Dominique, their experience brought great progress

15six_446

I go on alone, with the installation of the coolant expansion tank. Made of glass, it’s the kind of expansion tank fitted on various Renault cars during the fifties and sixties, for instance Renault 8 and Caravelle

15six_447

I make a bracket that uses two existing holes in the fire wall. The result looks strange, let’s say it’s art 😉

15six_453

And voilà ! I still have to fit a longer hose to hide it a little bit more. I may have to replace the hose because I’m not sure it will take the temperature correctly

15six_454

Before driving the car I sure have to install the licence plate. I used a french licence plate as a base, to avoid making additional holes in the trunk lid

15six_455

I was able to chose the number “15” in the licence number, that’s cool because it all depends on the goodwill of the person we meet at the licence office

15six_462

The quality of the new ignition wirings seems poor so I replaced it with a better one, with silicone wires

15six_463

On this side, I replaced the expansion tank hose by a longer one, it shows a little bit less that way

I also had an issue with the clutch, I modified the adjustment of the clutch control arm, the first and reverse gears are now easier to select, but this is also not perfect.

But brakes are working very well, the hydraulic system works like a charm, the expansion tank is working well too (the radiator seems to breath well).

This is very difficult to evaluate but I think this intervention represented about 300 hours of work. I spent the most part of my free time since last November. I think the result is good but we’ll see in the future if reliability is there.